How does an electric air compressor work? | Feyafy Compressor

In today’s industrial landscape, pneumatic systems rely heavily on air compressors, which play an essential role in workshops and manufacturing facilities worldwide. Yet this wasn’t always the case. Within the broader timeline of industrial machinery, compressors are a fairly modern innovation.

Prior to the advent of air compressors, tools were often driven by cumbersome assemblies involving belts, wheels, and other bulky mechanical parts. These systems were not only large and expensive, but also impractical for smaller businesses. Now, air compressors are available in a wide range of designs and capacities.

They’re used everywhere from automotive repair shops and industrial plants to home garages. This guide will explore the inner workings of air compressors—covering their fundamental principles and the distinct methods various compressor types use to displace air.

Think of the most powerful force in industry, and you might not picture air. Yet, compressed air is so essential it’s often called “the fourth utility.” It’s the invisible muscle behind countless moments in your day—from the draft beer at your local bar to the cars on the road and the devices in your home.

This is the power of modern air compressors: they turn simple air into a reliable source of energy that drives business forward. By optimizing your compressed air system—whether you’re running a small shop or a massive plant—you unlock serious benefits: major cost savings, a smaller energy footprint, and a more powerful operation. It all starts with understanding your air needs. Knowledge isn’t just power; it’s compressed air.

Understanding Air Compressor Fundamentals

At its core, an air compressor is a power conversion device. It uses an energy source—typically an electric motor, or a diesel or gasoline engine—to compress and pressurize air, transforming that power into stored kinetic energy. This energy is then released as controlled bursts or a continuous flow to power various tools and equipment. Common configurations include:

- Reciprocating/Piston Compressors: These models use a drive shaft, piston, connecting rod, and cylinder valve head working in tandem to generate pressurized air.

- Vacuum-Pump Compressors: This design creates pressure by evacuating air from a sealed system via a rotating shaft.

Two fundamental principles govern their operation: air pressure (often measured in pounds per square inch gauge, or psig) and airflow (typically measured in cubic feet per minute, or cfm).

While horsepower indicates the engine’s output capacity, the more critical metrics for predicting real-world performance are a compressor’s pressure (psig) and volume (cfm). For peak efficiency, the goal is to find a unit that delivers the highest pressure and volume using the least amount of horsepower.

When selecting a model based on its cfm and psig, also consider its operational noise level, which is rated in decibels (dBA) and can range from a quiet 64 dBA to over 130 dBA. Incorporating an auxiliary storage tank is a wise strategy, as it allows the compressor to cycle less frequently, reducing wear and tear and preventing overuse.

What Makes a Motor-Driven Air Compressor the Engine of Modern Industry?

Feyafy’s latest range of portable air compressors delivers reliable compressed air solutions for virtually any setting, even the most demanding oil and gas environments.

Virtually all air compressors qualify as motor-driven, as an engine or motor is fundamental to powering their core function.

This includes the most widespread industrial varieties—reciprocating, centrifugal, and rotary screw compressors. Even belt-driven models, such as our KRSB belt-drive rotary screw compressors, fall into this motor-driven category.

A critical factor in their application, however, is mobility. How easily can they be moved? Traditionally, these are large, heavy units permanently installed in dedicated machinery rooms and designed to be stationary.

Yet, the need for compressed air extends far beyond the factory floor. Its safety, efficiency, and adaptability are vital in fields like construction, mining, road work, and on oil and gas rigs, where portable power is essential.

How does an electric air compressor work?

The Mechanics of Piston Air Compressors

How does a piston-driven compressor generate power? The principle is elegant in its simplicity: it increases air pressure by dramatically reducing its volume. This is achieved through reciprocating piston action, the most common technology in compressors today.

- A power source, either electric or gasoline-driven

- Specialized inlet and discharge valves to control airflow

- A compression pump mechanism

- A storage reservoir for pressurized air

The process begins as the compressor pulls in ambient air, creating a vacuum that confines the air within a chamber. This trapped air is then compressed, and the resulting high-pressure air is forced into the storage tank. The unit automatically shuts off—a phase known as the duty cycle—once the tank reaches its preset maximum pressure. It reactivates only when the pressure falls below a specific threshold. It’s worth noting that while integral to most systems, storage tanks are omitted from some smaller, ultra-portable models to prioritize mobility.

Understanding Air Displacement

The fundamental operation of any compressor hinges on air displacement—the physical movement of air to pressurize it. This is accomplished through one of two primary methods:

- Positive Displacement: This is the predominant technique. Air is drawn into a chamber where its volume is mechanically reduced, thereby compressing it. The pressurized air is then transferred to a storage tank for on-demand use.

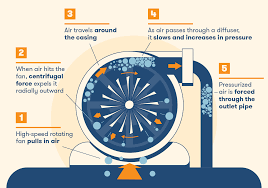

- Dynamic Displacement: Also referred to as non-positive displacement, this method utilizes a high-speed impeller with rotating blades to accelerate air into a chamber. The kinetic energy from this motion rapidly builds pressure. This efficient, high-volume approach is commonly used in turbocompressors, such as those found in automotive turbochargers.

Varieties of Positive Displacement Compressors

Given its prevalence, positive displacement technology comes in several forms, each suited to different tasks, from heavy industry to DIY projects.

- Rotary Screw Compressor: An industrial staple, these compressors feature two intermeshing screws that rotate in opposite directions. This motion draws air in, traps it between the screw threads, and compresses it as it is forced through the chamber. The air is then discharged into a storage tank. Most are oil-flooded for lubrication and cooling, though oil-free models exist. The technical process for oil-injected models involves air entering an inlet valve, mixing with oil, being compressed by the screws, and then passing through an oil separator and filter before emerging as clean, pressurized air.

- Rotary Vane Compressor: Operating on a similar principle, a rotary vane compressor uses a rotor mounted off-center within a circular cavity. Spring-loaded vanes slide in and out of the rotor, creating chambers of varying size. As the rotor turns, these chambers expand to draw in air and then contract to compress it against the outer wall before ejecting it. Their compact and simple design makes them ideal for contractors and homeowners.

- Reciprocating/Piston Compressor: Among the most common types, these use a crankshaft to drive a piston within a cylinder. The downstroke draws air into the chamber through an intake valve, and the upstroke compresses it and forces it out through a discharge valve. They can be single-stage (using one piston) or more powerful two-stage models (using two pistons for higher pressure).

Compression Cycles: Single-Stage vs. Two-Stage

- Single-Stage Compression: The air is compressed to its final pressure in a single piston stroke. This straightforward design is perfectly suited for private projects and lighter applications.

- Two-Stage Compression: Air is compressed in one cylinder and then moved to a smaller second cylinder for further compression. This allows for significantly higher pressures, making it ideal for factories. These systems often include an intercooler between stages to cool the air, increasing efficiency and preventing overheating.

The Role of the Regulator

A regulator, attached to the tank’s outlet, is the command center for pressure control. It features an adjustable knob and pressure gauge. Turning the knob clockwise increases output pressure by allowing more air from the tank through the valve; turning it counterclockwise restricts flow to lower the pressure. Most systems have a high-pressure switch (e.g., 125 psi) that shuts off the motor. The regulator allows you to set a lower, tool-specific pressure. A crucial companion to the regulator is the unloader valve, which releases trapped air from the compression chamber to prevent motor strain during startup.

Oil-Flooded vs. Oil-Free Lubrication

- Oil-Flooded (Lubricated) Pumps: These use oil to lubricate moving parts, enhancing durability. However, oil can carry over into the compressed air stream, which is beneficial for some tools but detrimental for applications like painting, woodworking, or food and pharmaceutical production, where contamination is unacceptable.

- Oil-Free Pumps: These compressors are equipped with permanently lubricated components or advanced coatings, eliminating the risk of oil contamination. They are essential for sensitive industries and provide clean air straight from the source.

Deciphering Power: Understanding CFM

While horsepower is often cited, a compressor’s true capability is better measured by its airflow, expressed in Cubic Feet per Minute (CFM). To account for real-world variables like heat and humidity, manufacturers use Standard Cubic Feet Per Minute (SCFM), a normalized rating. Other important metrics include Displacement CFM (a theoretical measure of pump efficiency) and CFM FAD (Free Air Delivery, which measures the actual air delivered to a tool).

Compressors vs. Pumps: A Key Distinction

- A pump moves liquids or gasses from one place to another.

- A compressor is specifically designed to reduce the volume of a gas to increase its pressure.

The Ubiquity of Compressed Air

Feyafy Compressor provides premium air compression solutions, including rotary screw, reciprocating, and oil-free models. Use our sales and service locator to connect with a certified dealer near you.