Searching for motor rewinding near me? Feyafy offers motor rewinding services in Dammam and surrounding areas. Our local services are fast, reliable, and affordable, ensuring that your motor gets back to work quickly.

We specialize in electric motor rewinding for all types of electric motors, including small, medium, and large-scale systems. Our expert technicians use the latest techniques to ensure your motor runs like new.

Feyafy offers industrial motor rewinding services for larger, more complex motors used in manufacturing and other industrial applications. We ensure that your motors are rewound to meet industry standards, improving efficiency and longevity.

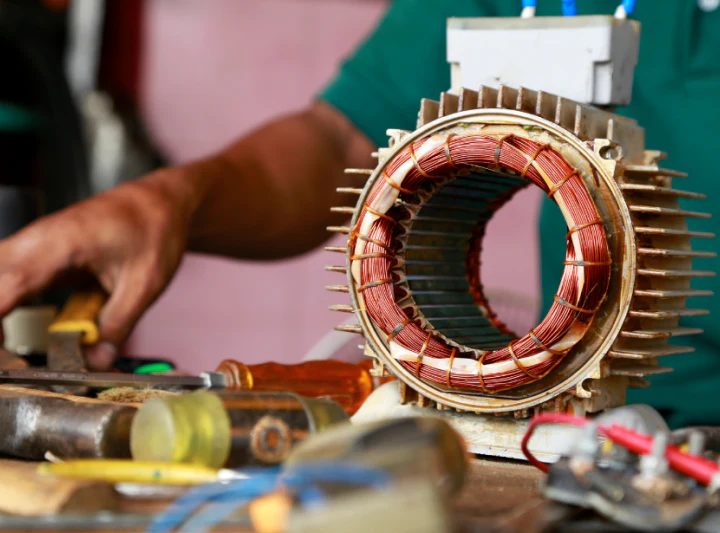

Our motor rewinding workshop is fully equipped with state-of-the-art tools and machinery to provide the highest quality rewinding services. We cater to both small-scale and industrial motor rewinding needs.

At Feyafy, we believe in providing affordable motor rewinding services without compromising on quality. We offer competitive pricing to ensure you get the best value for your investment.

Wondering about motor rewinding cost? At Feyafy, we provide transparent pricing for all our motor rewinding services. We offer competitive rates to ensure you get the best value for your money.

Rewinding your motor offers several benefits, including: Increased Efficiency: A rewound motor operates more efficiently, saving energy and reducing operating costs. Cost-Effective: Rewinding is often more affordable than purchasing a new motor. Extended Lifespan: Proper rewinding can extend the life of your motor, allowing you to get more use out of it.

The motor rewinding process involves several important steps to restore your motor to its original performance. Here's a brief overview of the motor rewinding process step by step: Disassembly: The motor is carefully disassembled, and the old windings are removed. Inspection: The motor components are thoroughly inspected for wear and tear. Rewinding: New wire is used to rewind the motor's stator and rotor.

At Feyafy, we provide high-quality motor rewinding services designed to restore your electric motors to their optimal performance. Whether you need electric motor rewinding, industrial motor rewinding, or three-phase motor rewinding, our team of experts is equipped to handle all your motor rewinding needs with precision and care.

If you’re in need of motor rewinding services or have questions about electric motor repair and rewinding, don’t hesitate to contact Feyafy. Our expert team is ready to assist you with all your Motor Re-Winding Works needs.

+966 13 8180844

info@feyafy.com

Conveniently schedule your service with us today. Our team is ready to assist with your HVAC, electrical,Motor Re-Winding Works and mechanical needs at your preferred time.

WhatsApp us